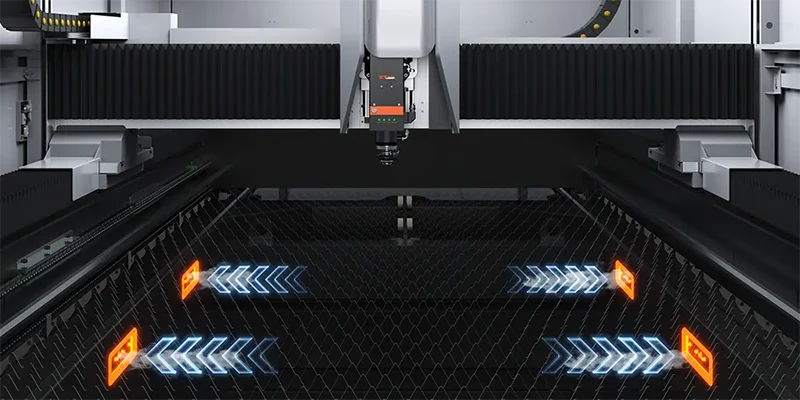

High-efficiency exchange table

Processing without smoke and dust

Z-axis modular sealing

High-efficiency exchange table

- The machine is equipped with two work tables of the same size, while cutting, workers can normally load/unload materials, realizing the cycle processing mode of loading/unloading materials while cutting.

- One worker can operate multiple machines at the same time, which saves labor costs and improves work efficiency.

Processing without smoke and dust

- The fully encompassing metal cover isolates the smoke and dust generated from the outside world, forming a closed processing environment, making the processing process more green and environmentally friendly.

- Effectively reduce the smoke and dust pollutants generated during machining.

Z-axis modular sealing

- Z-axis adopts precision sealing integration technology, integrating and encapsulating the core transmission components such as ball screws, linear guides, servo drives, etc., eliminating the assembly errors of the traditional split structure and ensuring that the geometric accuracy of the motion trajectory is within ±0.03mm.

- Multiple sealing protection, effectively blocking external dust intrusion.

| Model | XT-G1530 2.0 |

| Working Area | 1530×3050mm |

| Laser Power | 3-12kW |

| Fastest Platform Exchange Time | 25s |

| Z-axis Stroke | 370mm |

| Max Linkage Speed | 120m/min |

| Max Acceleration | 1.5G |

| Positional Accuracy | ±0.03mm/m |

| Re-positional Accuracy | ±0.03mm |

Aviation Aluminum Beam

Light weight, high strength, fast speed, can carry high intensity processing.

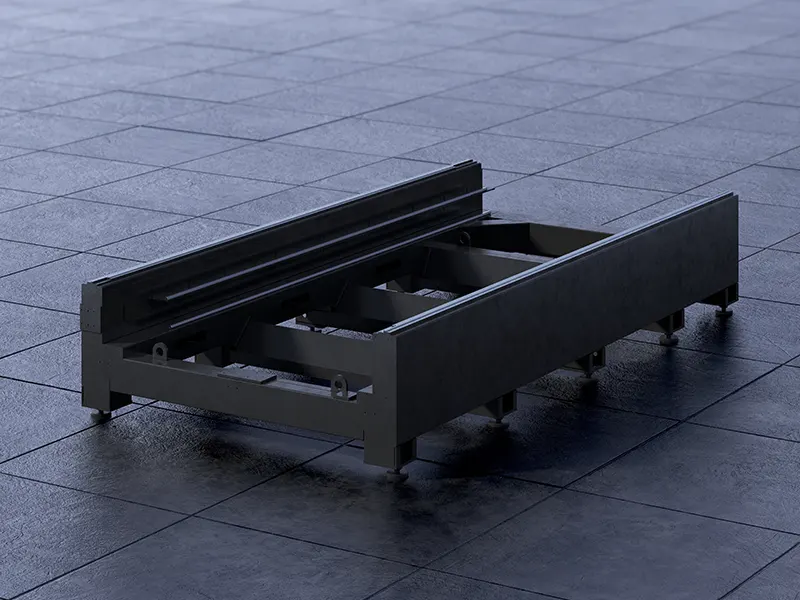

3.0 One-piece bed

The bed body is made of Q355 low alloy high-strength steel, molded in one-piece die-casting to form a sealed one-piece crate structure that is non-degenerative and more resistant to high temperatures.

Fully enclosed metal cover

The whole machine is equipped with an all-round metal cover around the machine, which can effectively block the smoke and dust pollution generated during the processing, making the processing environment more environmentally friendly.

Mechanical Advantages

This equipment is specially designed for the metal processing industry, and its body structure’s ability to resist deformation is 60% higher than before

Control System Advantages

The equipment is equipped with a professional control system and built-in multiple functions, which can greatly improve processing accuracy and efficiency, reduce failure rate and save costs.

Intelligent Centering

After scanning the edges of the sheet through the laser sensor, the system algorithm locates the geometric center of the sheet or workpiece, ensuring that the cutting path and material position are precisely matched, thus improving cutting accuracy and material utilization.

Focus Compensation

After scanning the edges of the sheet through the laser sensor, the system algorithm locates the geometric center of the sheet or workpiece, ensuring that the cutting path and material position are precisely matched, thus improving cutting accuracy and material utilization.

Traceless MicroLink

The surface of the metal workpiece after laser cutting is clean and remains partially connected to the remaining material, which prevents the workpiece from shifting and helps to achieve batch unloading and high-efficiency production.

Collision Avoidance Sensor

Real-time monitoring of the distance between the cutting head and the workpiece or table, and automatically adjusts the height or stops the machine before a possible collision to protect the cutting head and the workpiece from damage.